IST Metz GmbH & Co. KG

Booth number: HALL 4 - J423B

www.ist-uv.com/en/

About us

IST METZ is a leading international supplier of innovative UV, LED UV and excimer curing systems that offer efficient, sustainable and high-performance surface finishing solutions for numerous industries. With decades of experience in the development and integration of state-of-the-art curing technologies, IST METZ supports companies in optimising production processes, shortening throughput times and manufacturing high-quality end products with outstanding surface quality.

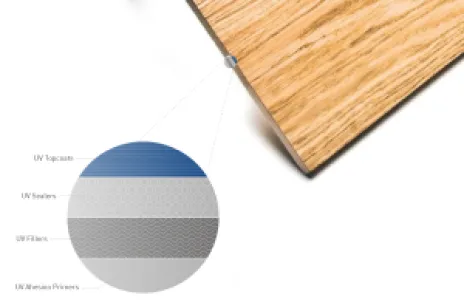

For the wood and flooring industry, IST METZ offers tailor-made solutions for the UV curing of coatings, varnishes, fillers and sealants that are specifically designed to meet the requirements of these industries. The technology is suitable for a wide range of applications – from the finishing of natural wood surfaces to the treatment of modern floor coverings.

A key advantage of IST technologies is the exceptionally fast curing using UV or LED UV radiation, which significantly increases production speeds while reducing energy consumption. The systems create durable, scratch- and chemical-resistant surfaces while improving the environmental balance of production through reduced emissions of volatile organic compounds (VOCs).

IST METZ offers a broad portfolio of solutions – from classic UV curing and LED UV systems to innovative excimer technology – and supports its customers with tailored advice, integration into existing production lines and after-sales services.

Address

Lauterstr. 14-18

72622 Nürtingen

Germany

E-mail: info@ist-uv.com

Phone: +49 7022 6002-0

Internet: www.ist-uv.com/en/

Silver 21/03-04, Wave One Tower, L-2A, Pocket - G, Sector - 18, Noida

201301 Gautam Buddha Nagar (U.P.)

India

E-mail: info@in.ist-uv.com

Phone: +91 120 5109125

Contact person:

Products & Services

Solutions for wood, wood-based materials and floor coverings

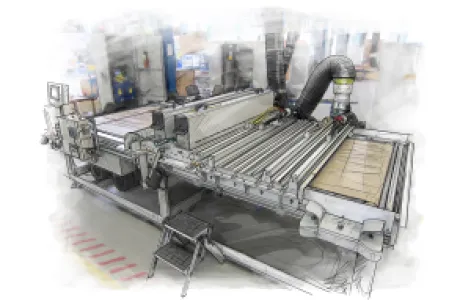

IST METZ offers a comprehensive portfolio of UV, LED UV and excimer curing systems for the industrial surface finishing of wood, wood-based materials and floor coverings. Our modular system solutions are suitable for paints, coatings, adhesives and sealants and can be flexibly integrated into new or existing production lines.

The product range extends from UV lamp and LED UV systems to inerting solutions and customer-specific system concepts for parquet, furniture components, panel materials and vinyl, SPC and WPC floor coverings.

Our technologies enable high line speeds, uniform curing, scratch-resistant surfaces and energy-efficient processes – for reliable series production and consistent product quality.

FREEcure - Sustainable UV curing Sustainable UV curing

In wood processing, the demand for resource-saving curing processes is constantly growing. UV curing of varnishes and coatings offers a proven solution here: it works quickly, is energy-efficient and ensures resistant, low-emission surfaces.

Our specialists have been working on the further development of UV systems for many years, focusing on ecological aspects – even before issues such as energy prices and CO₂ reduction became widely discussed. The result is innovative technologies that are sustainable and at the same time meet the highest production requirements. One example is the FREEcure system, developed in collaboration with BASF, which can significantly reduce energy consumption and is becoming increasingly established in the wood and wood-based materials industry.

Particularly in the case of 100% UV systems in high-speed rolling lines in furniture production, it is worthwhile reducing the proportion of photoinitiators (to around a quarter to a third). This allows the desired production speed to be achieved with fewer UV units – with a clear focus on energy savings. With FREEcure, production speeds of 30 to 50 m/min per unit can be achieved, meaning that in many cases only two to three units are required. For special applications, it also makes sense to combine this with LED UV technologies in order to reliably cure thicker layers.

Rely on future-oriented UV curing that combines sustainability, efficiency and cost-effectiveness in the wood industry.

EXIcure - for perfect surface finishing

EXIcure from IST METZ offers innovative UV excimer technology for surface treatment in the wood, furniture and flooring industries. With a working width of up to 4 metres, it produces streak-free, matt and abrasion-resistant surfaces without the use of chemical matting systems.

Advantages at a glance:

Matting and anti-fingerprint effect thanks to 172 nm UV radiation

Gentle on sensitive materials

Seamless integration into production lines

Environmentally friendly and efficient finishing

Applications: Parquet, laminate, furniture, veneers and functional films – for high-quality, durable surfaces.

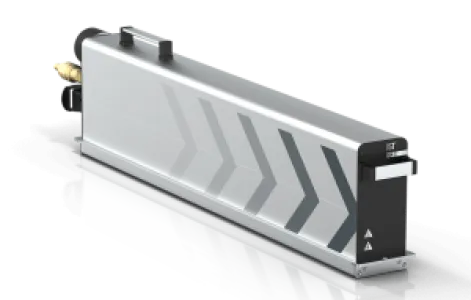

MBS L: Air cooled UV system up to 1600 mm

Applications in industrial environments require reliable and cost-consciously designed technologies. The MBS L represents a powerful air-cooled UV unit with a lamp length of 550 to 1600 mm and a maximum lamp output of 200 W/cm.

The MBS L features odour extraction and ozone extraction, which simultaneously cools the lamp and the reflector.

BLK - Water-cooled UV system for industry

The BLK UV system is a powerful and energy-efficient solution for demanding industrial applications. It offers up to 240 W/cm lamp power, a total of up to 36 kW and lengths of up to 2.4 m, making it one of the most powerful UV drying systems on the market. Thanks to its compact design, the system can be easily integrated into machines while reducing the necessary exhaust air requirements and operating costs.

The modular design allows for flexible use – even as a hybrid solution with LED UV technology. Highlights include HotSwap control, fast lamp change (FLC), intelligent IPS control and URS reflector technology for optimum radiation effect. Efficient water cooling ensures excellent heat management, minimises thermal stress on the substrate and optimises UV performance in a wide range of printing and industrial processes.

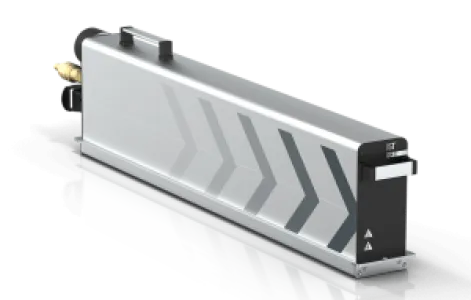

LEDcure NX – Water-cooled LED UV system

The LEDcure NX from IST METZ is a state-of-the-art, water-cooled LED UV curing system that combines maximum efficiency with future-proofing. Thanks to the use of powerful LED technology, the system achieves very high light output while consuming little energy — ideal for energy- and cost-conscious production processes. Thanks to its modular, flexible design, the LEDcure NX can be adapted in many ways, both in new systems and when retrofitting existing machines. The optimised radiation characteristics ensure uniform and reliable curing, even in demanding applications. With innovative features such as AI-supported SMARTcure technology for efficiency and service life optimisation, as well as outstanding investment and future-proofing, the LEDcure NX is a sustainable UV curing solution for modern industrial and wood production processes.