Paul Maschinenfabrik GmbH & Co. KG

Booth number: HALL 4 - H416A

circular-sawing.paul.eu/

About us

For more than 100 years, the name PAUL has stood for uncompromising quality, precision, and innovative strength in wood processing. As a Southern German mechanical engineering company with around 300 highly qualified employees, we develop and manufacture high-performance solutions for the most demanding industrial applications.

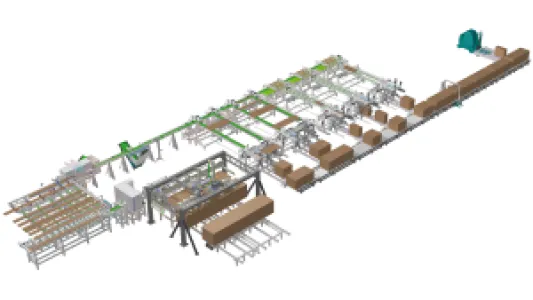

Our portfolio ranges from industrial circular saw machines for rip cutting and precision cross-cut saws to complex edging and cross-cutting systems, which are used worldwide in sawmills and in downstream processing industries.

Optimized yield and maximum profitability are key performance factors in your production. PAUL rip-cutting and cross-cutting systems stand for outstanding reliability, precision, and state-of-the-art user friendliness.

Modular, expandable machine components, combined with highly efficient and high-speed mechanization systems, ensure maximum performance and provide you with a decisive competitive edge.

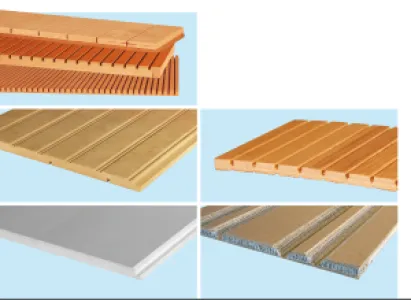

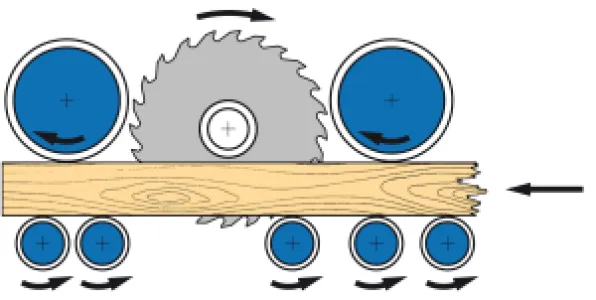

Our multi-blade circular saws set new benchmarks, offering cutting widths of up to 3,000 mm. They guarantee maximum efficiency and precision when processing solid wood, particle board, MDF, and many other materials.

PAUL – Machines that set standards. For Generations.

Address

Max-Paul-Strasse 1

88525 Dürmentingen | Germany

Germany

E-mail: holz@paul.eu

Phone: +49 7371 500-0

Internet: circular-sawing.paul.eu/

Contact person:

Manfred Buck

Sales Director

E-mail: mb@paul.eu

Products & Services

We are one of the world’s leading manufacturers of circular sawing machines and systems for industrial processing of wood and plastics, as well as machines and equipment for the production of prestressed concrete.

We employ a total workforce of 290, making us one of the major employers and training centres in the district of Biberach.

Our company aim was and still is to open up new markets and to be in the forefront with cutting-edge concepts. With a worldwide export ratio of 85% we assume a leading position in global markets with both of our product divisions of woodworking machinery and prestressed concrete production systems. Our machines are found in almost all the countries of the world.

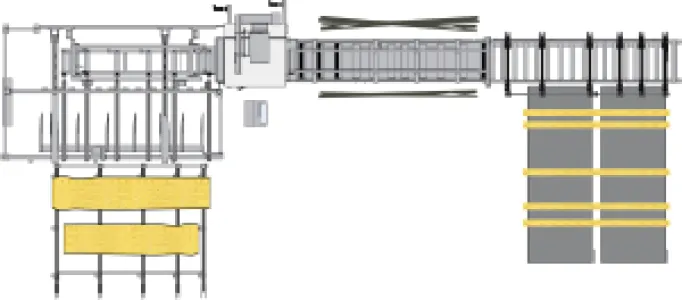

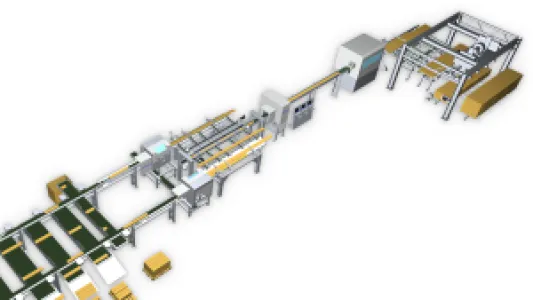

PANEL PROCESSING

We supply machines for ripping all kinds of panels. As the fields of application are both varied and highly individual, we offer a suitable solution to cover every kind of assignment. Our supply range encompasses not only stand-alone machines but also project-processed complete solutions offering a high degree of automation.

These machines are used in all fields of industry: in sawmills and in the furniture industry, for the production of parquetry and laminated flooring, pallets, concrete moulds, kitchen front panels, glued up panels, cement-bonded particle boards, profile strips, door skins, in packaging, window, bed and coffin factories, in the plastics, WPC, OSB, OSL, LVL panel or cardboard industry and in many other applications areas.

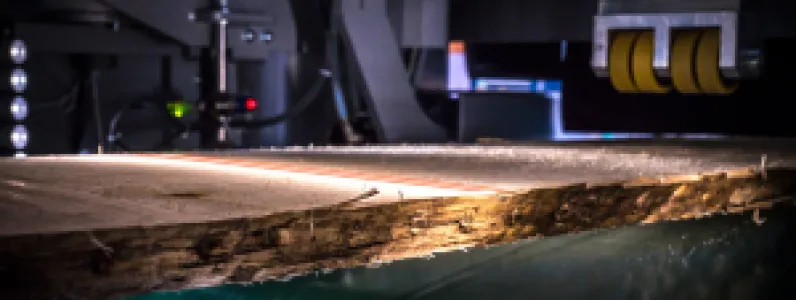

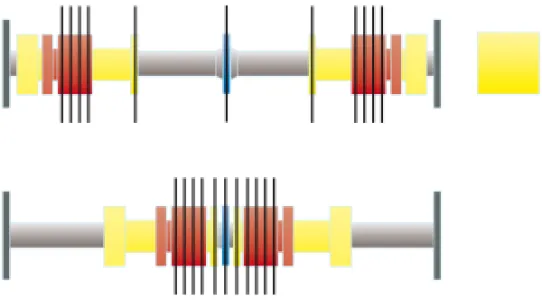

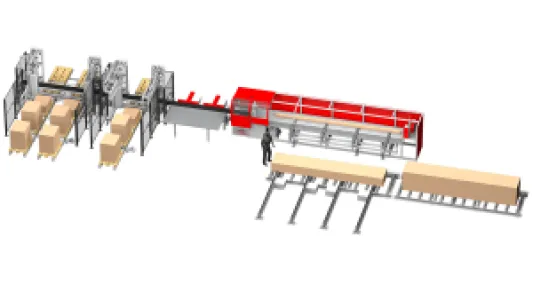

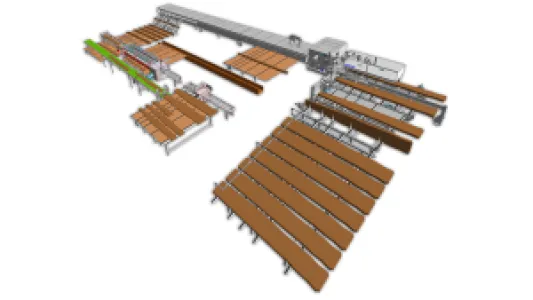

SOLID WOOD RIPPING

Our machines can be loaded either manually, semi-automatically or fully automatically. We can also supply edging systems for combined resawing, where one machine can be used for edging boards and also for resawing cants. The number of movable saws in the circular edger or in the resaw can be adapted to the customer's requirements. Telescopic saw bush setups are also part of the standard product portfolio. On the other hand, pure multirip saws with a fixed saw setup are also available.

As a specialist for solid wood cutting, we offer individual solutions for both softwood and hardwood. Depending on the specific requirements, we use climb-cutting technology or technology cutting against the feed.

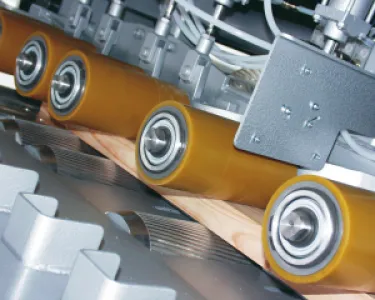

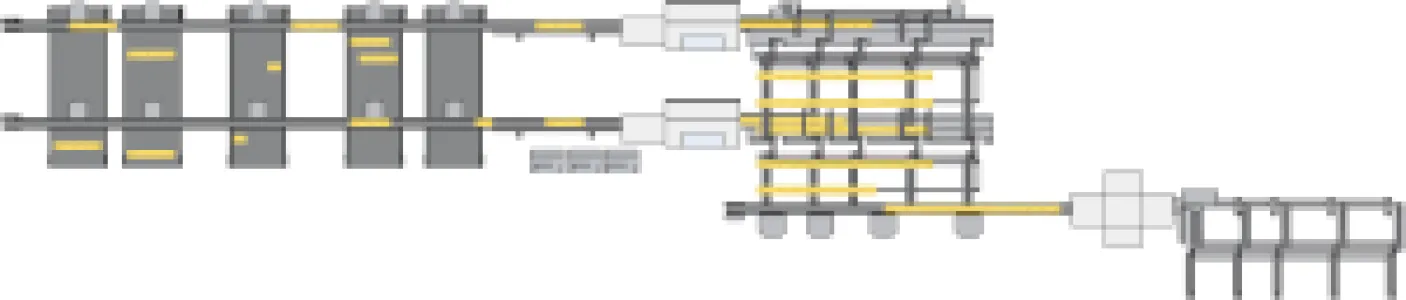

OPTIMIZED CROSS_CUTTING

Paul is your competent cross-cut saw supplier for industrial use. Whether manual undertable cross-cut saw with classic two-handed control or fully automatic CNC cross-cut system with crayon line marking or scanner for automatic defect and dimension detection - we have the right machine for every requirement. Depending on the application, we offer optimizing cross-cut saws with roller feed as well as with positioning pusher. Optimizing cross-cut saws with roller feed are particularly suitable for applications in which defects are to be cut out. CNC cross-cut systems with positioning pusher, on the other hand, can process boards in packs and are also very precise.

As one of the very first CNC cross-cut system manufacturers in the woodworking industry, Paul's focus was on maximizing machine performance and timber yield by means of special optimization programs. The corresponding optimization algorithms have been continuously developed so that optimizing cross-cut saws from Paul set their own standards.

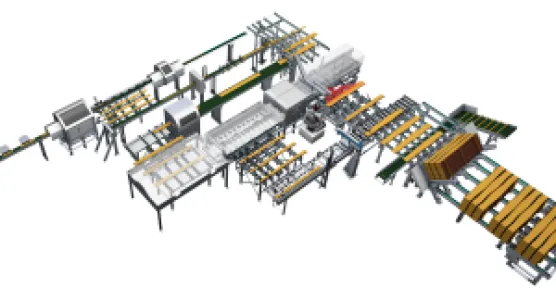

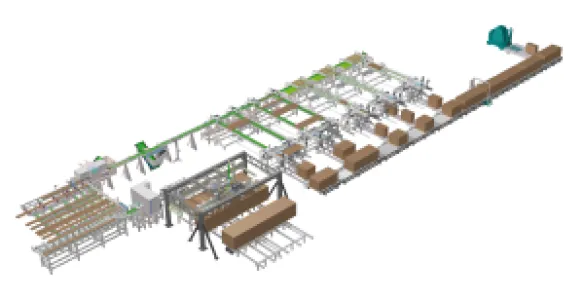

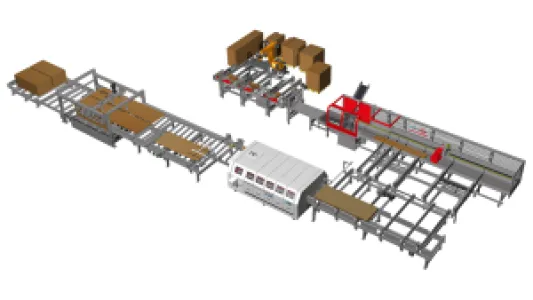

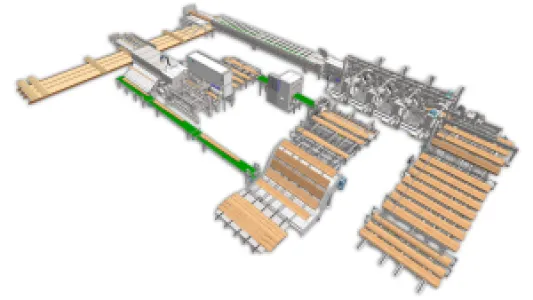

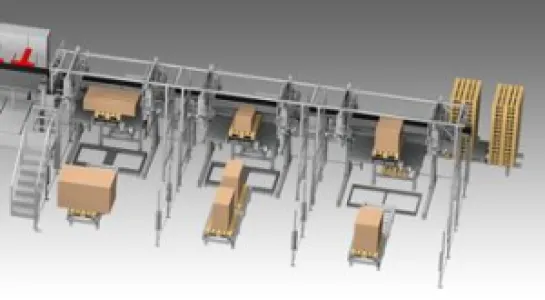

SYSTEM SOLUTIONS

Automated complete solutions are implemented through interlinking of automated handling equipment, cross-cut systems and ripsaws. Components from other manufacturers are integrated, where necessary. Higher feed rates, interlinked processing steps, accurate workpiece guidance and automatic work flows lead to a significant improvement in productivity. Operator workload is reduced and the standard of security increased.

To enhance competitiveness, special solutions are often called for. We not only supply stand-alone machines, but also engineer complete custom-tailored high-performance systems with maximum uptime. The degree of automation is suited to the application concerned, ranging from partial automation through to fully automated high-end solutions. We develop, design and manufacture the majority of the system components in-house or work together with well-known suppliers, thus offering complete solutions from a single source.

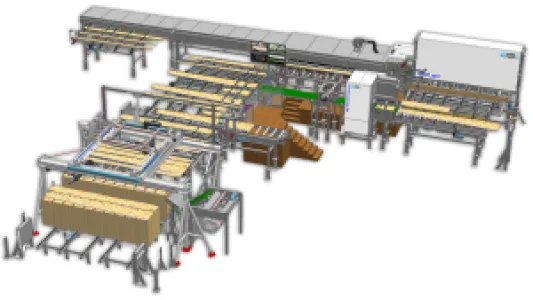

MECHANISATIONS / FEEDING / SINGLING

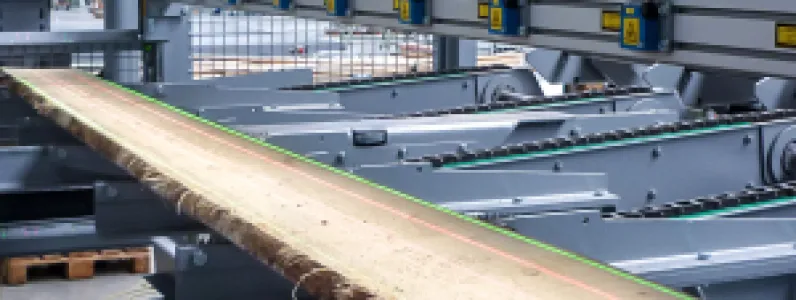

Optimum performance combined with maximum material yield and profit maximization is the objective of an automatic feeding system. In combination with different PAUL ripsaws, it is possible to develop a suitable solution for every requirement. Especially in the sawmilling industry an automated complete solution nowadays plays an increasingly important role. With rising raw material prices and large purchase quantities of the raw material wood, it must be ensured that storage times are reduced and throughput times increased. Automatic feeding systems improve the material flow and ensure an optimum timber yield.

The AB-MA_EXT was specifically designed for the optimized feeding of high-grade timber. In combination with PAUL ripsaws, these systems can be operated either fully automatically or with manual intervention. The workpieces are first measured automatically. By means of laser lines it is then indicated to the operator where cutting will be effected. If he does not agree to the cutting pattern suggested, he can easily adjust it from his seat using a joystick.

In times of ever-increasing performance requirements and the ever-increasing demand for maximum operating convenience in the sawmill, PAUL has developed the so-called semi-automatic infeed system (SAB). The operator can feed the workpieces into the ripsaw, align and, if necessary, turn them from his seat using a joystick. This convenient mode of operation increases the performance of the system and helps maintain a high work morale in the 21st century.

Automatic panel feeding systems are primarily used for the fully automatic loading of multirip circular saws. The complete panel stacks are transferred to the system where the panels are pushed off one at a time by an automatic pusher, automatically aligned and fed into the multirip saw. Thanks to the automated workflow, manpower costs are drastically reduced.

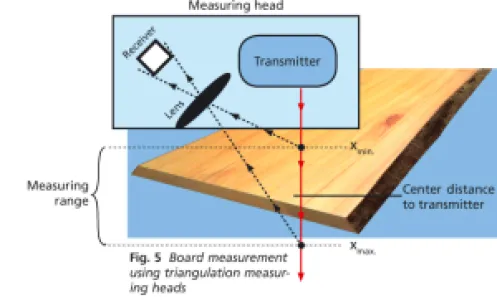

MEASURING & SCANNING

The PAUL Rip Scanning System detects edged and unedged boards in the longitudinal passage. Special algorithms for the ripping process calculate the best optimization result. Subsequently, an automatic infeed system, which detects the position of the workpieces, feeds them to a rip saw. Taking into account the previously calculated optimization, the infeed system turns and positions each individual board in the optimal position.

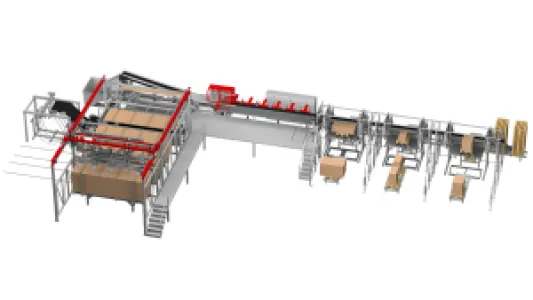

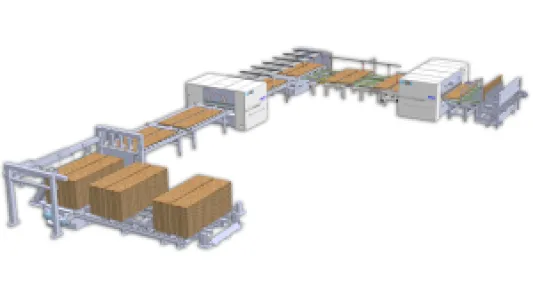

SORTING & STACKING

We develop stackers for the automated stacking of workpieces and use on the outfeed side of cross-cut systems. They can be employed for order picking, temporary storage or preparation of the cut pieces for transport. The cut pieces are pushed from the sorting belt onto the stacker, arranged in layers and deposited on pallets or alike. An optional stick magazine places stabilization sticks after every preset number of layers.

The ZSA automatic stacker is suitable for stacking boards of different lengths in layers. With the stick magazine, which is available as an option, stabilizing sticks are inserted according to the programmable number of layers. The mechanism automatically adjusts to the board length to be stacked. The desired stacking height can also be preset. In addition, workpieces of different widths can be stacked in one layer. The system can also be retrofitted into existing lines. Due to the particularly economical design, the payback period of these automation components is especially short.

To achieve maximum system performance, push-feed cross-cut systems usually process the workpieces in packs. This means that several pieces are loaded side by side and one upon another. The packs are automatically cut at once and, accordingly, also need to be stacked in packs. Suitable solutions which can be extended by options such as automatic stick placement systems, automatic pallet feeders and many more reduce labour costs and considerably optimize the material flow in the factory.

Vacuum gantry systems are ideally suited for the automation of the destacking/stacking operation upstream and downstream of the circular sawing machine. They work fully automatically, require very little maintenance, can be used flexibly and are capable of handling heavy loads. Even workpieces with sensitive surfaces can be processed with ease. Sticks contained in the stack can be automatically removed and bundled, if required. We configure the appropriate vacuum gantry to individual customer requirements, whether for solid wood or panel applications.