Wandres GmbH

Booth number: HALL 4 - H418

www.wandres.com

About us

Founded 45 years ago, the original motivation and innovative spirit of Claus G. Wandres is as much in evidence within the company today as ever: “We provide the very best cleaning technology wherever particles and dust on surfaces cause flaws and rejects during production.” Today our machines are developed and produced at a new site in Stegen with the help of more than 140 highly motivated employees and cutting-edge production technology. The diversity of our modern family-run business is a unique feature of the company. We are fully aware of the importance of our local production sites and of the responsibility we have in the community for preserving and expanding local structures. An unusually high degree of vertical integration not only secures the high quality standards of our machines but also protects a large number of interesting jobs and training opportunities. As a regional company we value the advantages offered by geographic proximity such as short distances and lower costs for transport and storage infrastructure, as well as the availability in the region of first-class partners in industry. At the same time, Wandres is a key player globally and has founded two subsidiaries abroad, one in the USA and one in China. We also collaborate with sales and business partners internationally.

Address

Im Gewerbepark 8

79252 Stegen

Germany

E-mail: sales@wandres.com

Phone: +49 7661 9330-0

Internet: www.wandres.com

#333,9th cross,4th Main road,4th Phase

Peenya Industrial Area

560058 Bengaluru

India

E-mail: pandu@stileswoodworking.in

Phone: +91 95135 58797

Contact person:

Martin Tritschler

E-mail: m.tritschler@wandres.com

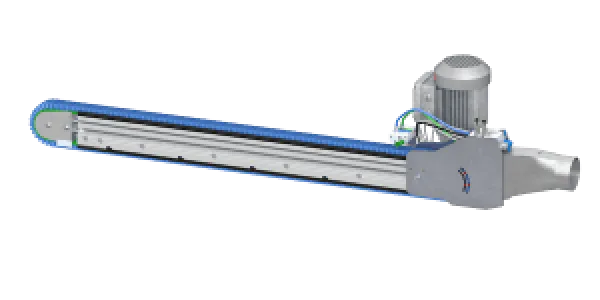

Sword Brush®

This sword-shaped brush cleans, for instance, boards and panels crosswise to the direction of transport in continuous operations in industrial production. The filaments of the circulating linear brushes are micro-moistened and effectiveley remove particles and fine dust. In a self-cleaning unit filaments undergo continouos regeneration. Particles are detached from the brush and disposed of via vaccum extraction.

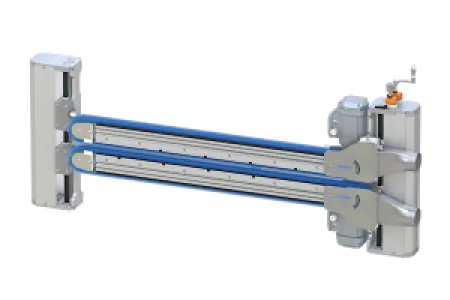

Combi Sword Brush

The Combi Sword Brush has a modular design. It consists of an adjustment unit with up to four cleaning units. Sword brushes and tornado channels can be combined to achieve the best possible cleaning results.

Features:

Single or double-sided cleaning

Can be combined with upstream air technology

Short parts from approx. 240 mm

Nominal widths up to 4500 mm possible

Optional electric heigth adjustment or pneumatic quick adjustment

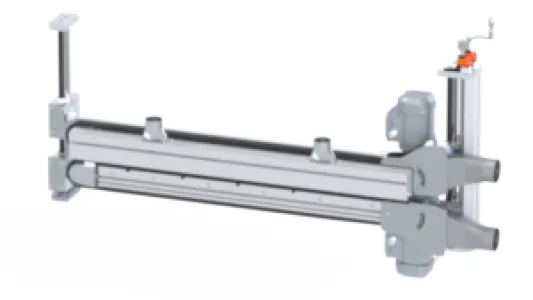

Tornado-Channel

High-speed rotating tornado nozzles or fixed power nozzles use compressed air to powerfully remove particles from product surfaces and recesses. The loosened particles are transported to the extraction system and removed from the production environment.

Features:

Compressed air-powered nozzles combined with powerful extraction.

The particles are reliably transported to the extraction system by a cross-flow in U-shaped profile.

Tornado-Channel TKF 200 with fixed power nozzles and integrated pressure tank for sudden, air-based cleaning of panels with rows of drill holes that are transverse to the direction of transport.

Tornado-Channel TKR 200 with electrically driven, rotating tornado nozzles for air-based pre-cleaning of panels with recesses, e.g. kitchen fronts or textured panels.

Combi Sword Brush Una U

During drilling, milling and sawing, large amounts of chips and dust particles occur which hamper production processes and lead to a loss in quality. If parts are stacked, particles are pressed into the surfaces and may damage them. During transport, particles oftentimes cause scratches. Wandres‘ Combi Sword Brushes provide for perfectly clean surfaces in industrial productions. The Combi Sword Brush Una U 121 with its micro filaments effectively removes particles and dust without using any cleaning agents. This machine is suitable for industrial 24/7 operations, has a low purchase price and provides for high performance cleaning results over long periods of time.