FREEcure - Sustainable UV curing Sustainable UV curing

Exhibitor

IST Metz GmbH & Co. KG

In wood processing, the demand for resource-saving curing processes is constantly growing. UV curing of varnishes and coatings offers a proven solution here: it works quickly, is energy-efficient and ensures resistant, low-emission surfaces.

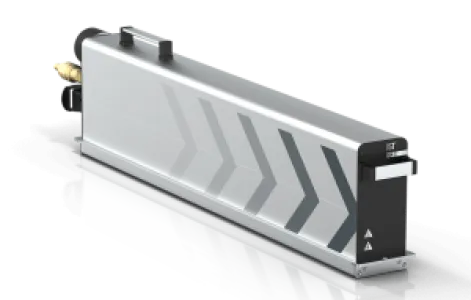

Our specialists have been working on the further development of UV systems for many years, focusing on ecological aspects – even before issues such as energy prices and CO₂ reduction became widely discussed. The result is innovative technologies that are sustainable and at the same time meet the highest production requirements. One example is the FREEcure system, developed in collaboration with BASF, which can significantly reduce energy consumption and is becoming increasingly established in the wood and wood-based materials industry.

Particularly in the case of 100% UV systems in high-speed rolling lines in furniture production, it is worthwhile reducing the proportion of photoinitiators (to around a quarter to a third). This allows the desired production speed to be achieved with fewer UV units – with a clear focus on energy savings. With FREEcure, production speeds of 30 to 50 m/min per unit can be achieved, meaning that in many cases only two to three units are required. For special applications, it also makes sense to combine this with LED UV technologies in order to reliably cure thicker layers.

Rely on future-oriented UV curing that combines sustainability, efficiency and cost-effectiveness in the wood industry.

FREEcure (photoinitiator-free or -reduced): UV curing without photoinitiators and no inertisation