SORTING & STACKING

Exhibitor

Paul Maschinenfabrik GmbH & Co. KG

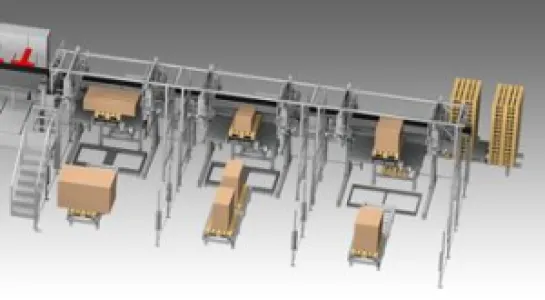

We develop stackers for the automated stacking of workpieces and use on the outfeed side of cross-cut systems. They can be employed for order picking, temporary storage or preparation of the cut pieces for transport. The cut pieces are pushed from the sorting belt onto the stacker, arranged in layers and deposited on pallets or alike. An optional stick magazine places stabilization sticks after every preset number of layers.

We develop stackers for the automated stacking of workpieces and use on the outfeed side of cross-cut systems. They can be employed for order picking, temporary storage or preparation of the cut pieces for transport. The cut pieces are pushed from the sorting belt onto the stacker, arranged in layers and deposited on pallets or alike. An optional stick magazine places stabilization sticks after every preset number of layers.

The ZSA automatic stacker is suitable for stacking boards of different lengths in layers. With the stick magazine, which is available as an option, stabilizing sticks are inserted according to the programmable number of layers. The mechanism automatically adjusts to the board length to be stacked. The desired stacking height can also be preset. In addition, workpieces of different widths can be stacked in one layer. The system can also be retrofitted into existing lines. Due to the particularly economical design, the payback period of these automation components is especially short.

To achieve maximum system performance, push-feed cross-cut systems usually process the workpieces in packs. This means that several pieces are loaded side by side and one upon another. The packs are automatically cut at once and, accordingly, also need to be stacked in packs. Suitable solutions which can be extended by options such as automatic stick placement systems, automatic pallet feeders and many more reduce labour costs and considerably optimize the material flow in the factory.

Vacuum gantry systems are ideally suited for the automation of the destacking/stacking operation upstream and downstream of the circular sawing machine. They work fully automatically, require very little maintenance, can be used flexibly and are capable of handling heavy loads. Even workpieces with sensitive surfaces can be processed with ease. Sticks contained in the stack can be automatically removed and bundled, if required. We configure the appropriate vacuum gantry to individual customer requirements, whether for solid wood or panel applications.